Solutions

Transforming Challenges into Scalable Solutions

From laser beam shaping to real-time process monitoring, our solutions bridge advanced research and practical application—empowering innovation at every stage of manufacturing.

Freeform Laser Beam Shaping

Current commercial laser powder bed fusion (LPBF) devices face issues with non-uniform thermal conditions due to Gaussian laser intensity distributions. This causes overheating and metal evaporation at the beam’s center and underheating at the edges, leading to small hatch distances, reduced productivity, and increased heat-affected zone (HAZ) size. These factors contribute to defects like cracks in Nickel and Al alloys and crystallization in bulk metallic glasses (BMGs).

At SAMC, we improved this by using a spatial light modulator to alter the laser beam’s shape and energy distribution. This project, in collaboration with IRPD and Innosuisse, was tested on materials like Nickel superalloys and BMGs, resulting in a publication in Advanced Functional Materials (impact factor 20). This demonstrates the technology’s potential to advance manufacturing research.

Blue laser processing

At SAMC, we focus on advancing laser-based manufacturing, especially in welding and additive manufacturing. We offer state–of–the-art blue laser facilities with various power outputs and beam qualities. Blue lasers are highly effective with reflective materials like copper, aluminum, and gold, creating stable melt pools crucial for precise manufacturing.

Our blue laser technology addresses challenges faced by both industry and research when using infrared or green lasers. Unique in Switzerland, SAMC’s facilities and ongoing development efforts support a range of applications and research, including 3D printing with blue lasers, welding with controlled atmospheres, and the manufacturing of dissimilar components and new materials. Note that some research activities are unfunded.

Process monitoring

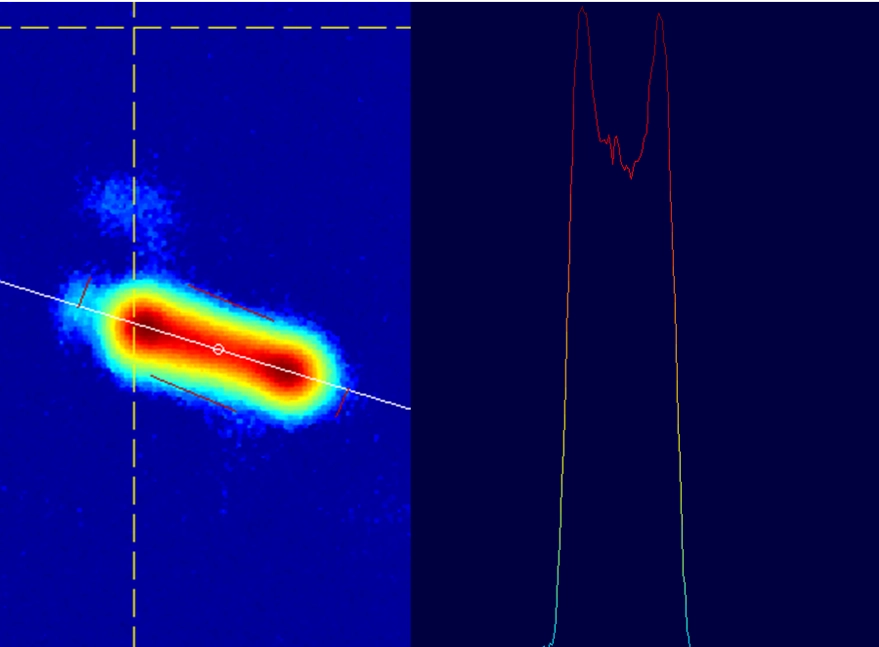

At SAMC, we deeply analyze data from various sensors during the LPBF process, going beyond standard machine capabilities. While different machines come with varying sensors, we develop custom code to better read, process, and interpret the data, even from sensors not typically accessible through provider software. This allows us to fully control and adjust machine parameters as needed, offering researchers a powerful tool to optimize their tests. The processed data provides valuable insights into the process and the impact of modifications.

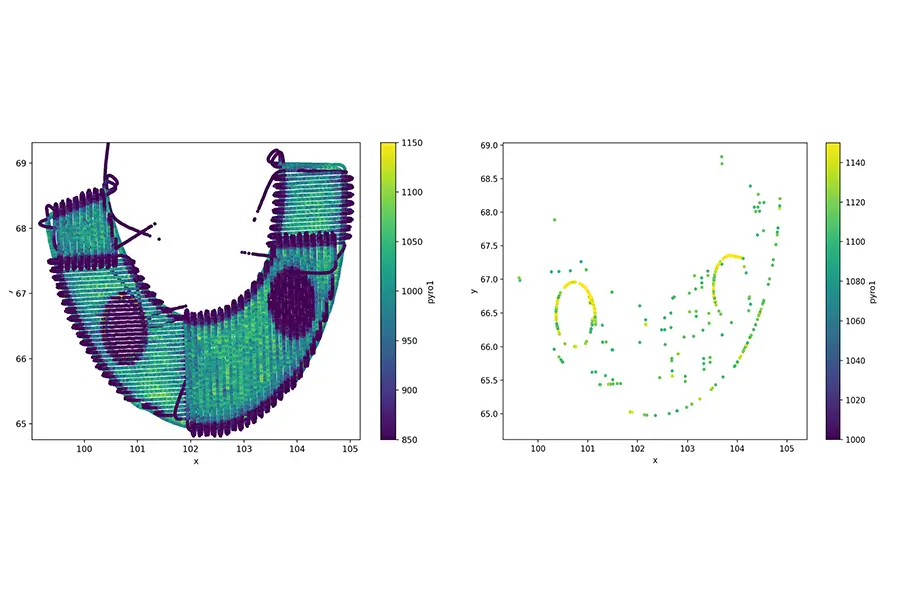

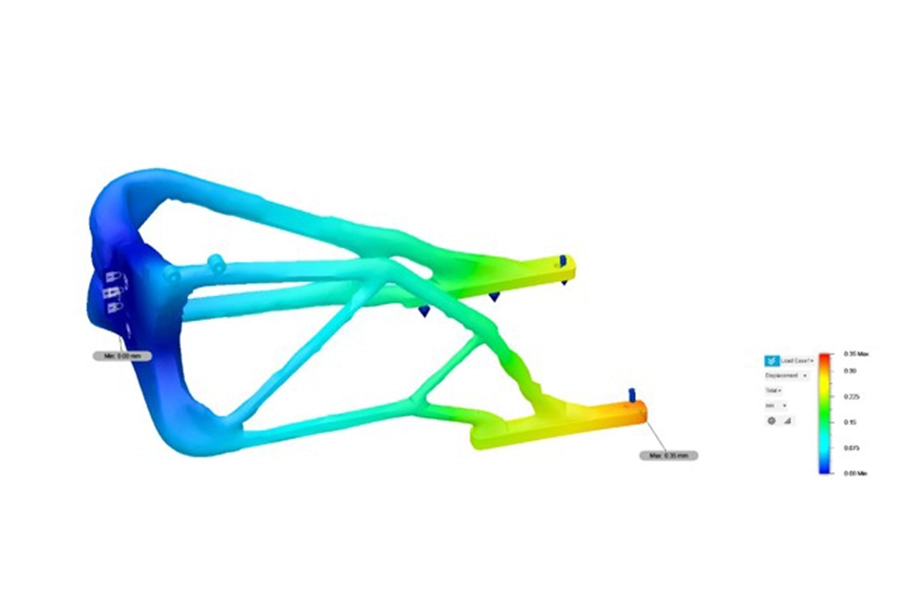

Design and Simulation

At SAMC, we integrate design for Additive Manufacturing (DfAM) with advanced thermal and mechanical simulations to create lightweight, reliable, print-ready components. By simulating the entire process, we can accurately predict potential deformations and pre-compensate for them in the designphase. This approach minimizes trial-and-error, ensures dimensional accuracy, and streamlines the path from concept to final part.

Full chain LPBF manufacturing

Our full chain LPBF (Laser Powder Bed Fusion) manufacturing approach spans the entire process—from design, simulation and material selection to printing, post-processing, and final partvalidation. We go beyond the lab by closing the loop through technology transfer to industry,ensuring that our innovations lead to real-world impact. This integrated workflow enables fasterdevelopment, higher quality, and tailored solutions for industrial needs.

Do you require advanced manufacturing to unleash your project’s potential?

Head of Swiss Advanced Manufacturing Center,

Partner, Executive Board Member