MPS system

The MPS is an all-in-one system that combines laser sources, motion modules, and control units in a single compact housing. This versatile and modular design enables the system to be configured for various applications, including welding, cutting, drilling, and structuring. It offers four different motion systems, ranging from a basic single Z-axis module to a high-precision granite setup with a cross table featuring linear servodriven axes and ±1 micron repeat accuracy. Researchers can choose between fixed optics or galvo scanners for each configuration. The MPS supports a wide range of laser sources, such as femto lasers, fiber lasers, pulsed solid-state lasers, and diode lasers.

Select Laser Welder

The Select laser welding system is a fully integrated, ergonomically designed laser welding system, with four high-precision axes, short setup times and easy CNC programming. Depending on the configuration, the Select can run in the following operation modes:

- Manual Laser welding

- Semi-automatic Laser welding via joystick control

- Fully automatic Laser welding via CNC control

The laser system is designed specifically for welding metals and metal alloys such as steel, gold, platinum, titanium, aluminium and copper. This welding can be done either with or without filler wire. The compact housing contains the laser source, power supply, cooling system, fume extraction, viewing optics and working chamber.

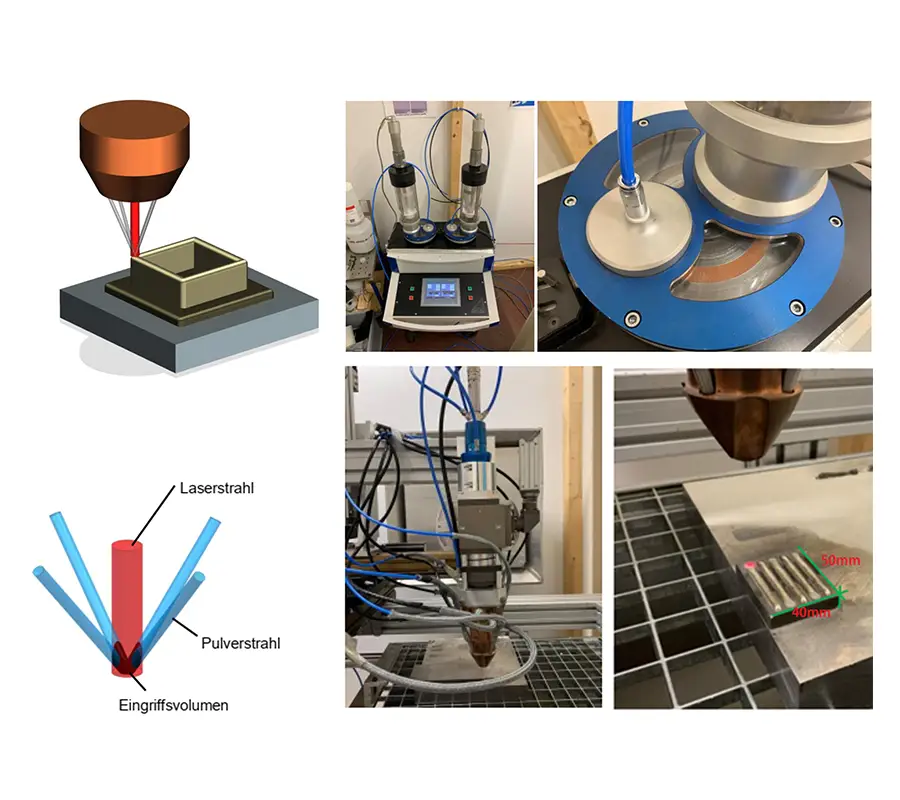

Two material cladding setup

At SAMC we have the cladding tool with the possibility of injecting two different materials during the process. The setup has been developed in collaborative work with BFH. This tool provides flexibility in application of different laser sources and materials, opens opportunities for conducting experiments on developments of new materials especially in-situ alloying for cladding and direct energy deposition 3D printing.

Blue laser welding station

Presently, both industrial and research communities encounter various challenges when fabricating parts from reflective materials, using infrared (IR) or even green laser technologies. SAMC blue laser facilities and expertise stand out as a game-changer in overcoming these challenges. SAMC not only provides different laser sources which are unique in Switzerland, but constantly tries to develop new technologies on this topic beside providing extensive support for various application.